Design Molded believes strongly in the notion that quality parts depend on a quality tool. We take seriously our customers’ investment in tooling and we understand the value that robust tooling can add to a program. We are proud to be an integral part of the product development process and we take complete ownership of the specification, design, build, and preventive maintenance of our customers’ tooling.

Custom Tooling

Custom Tooling

Our tooling department is built around highly skilled Toolmakers and state of the art equipment. Our talented staff bridges the gap between technology and experience, tackling challenges that many of our competitors cannot. We offer complete turn-key tooling services at a competitive price and lead time.

Our tooling department is built around highly skilled Toolmakers and state of the art equipment.

We respect the value of our customers’ tools and we take great pride in how we maintain them. We are able to prolong the life and productivity level of our customers’ tooling via our preventive maintenance program. We are experts at maintaining tooling with challenging features such as diamond finished surfaces, complex actions and electronics. There is no extra cost for first class maintenance – it is a service included in our thorough value driven pricing structure.

New Tooling/Revisions

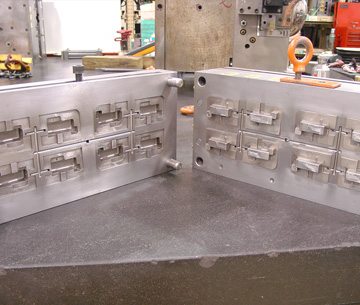

Design Molded offers a fully equipped and staffed new construction department. We work closely with our engineering staff from the initial design concept to the detailed mold design to enhance robustness, manufacturability, and maintainability. We manufacture tooling components directly from the solid model designs by translating tooling geometry to our machining centers and high speed graphite mills. We have full wire EDM and sinker EDM capabilities along with various finishing services such as surface grinding, diamond polishing, and final fitting.

Tool Maintenance

We respect the value of our customers’ tools and we take great pride in how we maintain them. We are able to prolong the life and productivity level of our customers’ tooling via our preventive maintenance program. We are experts at maintaining tooling with challenging features such as diamond finished surfaces, complex actions and electronics. There is no extra cost for first class maintenance – it is a service included in our thorough value driven pricing structure.

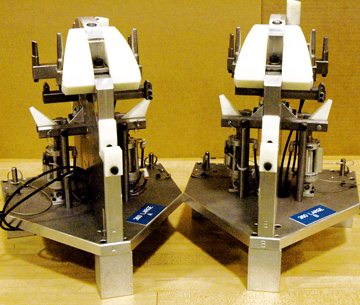

Fixtures

Design Molded Plastics has the ability to fabricate fixtures and end-of-arm robotic tooling in-house. It’s all part of our systems approach, in which we pay attention to every detail and maintain control of the process. It’s how you can be sure you are receiving – and supplying – a part that will do its job. So you can be confident in your relations with your customers.

We support our quality systems and our engineering with:

- Design assistance

- Prototype and machining of parts

- Fixtures

- Gauges